Hello, this is my first post here! I am trying to build a sub box for my sons truck. It is his first truck, and we got him his first sound system for Christmas. There is of course size restraints on the box dimensions and I just want to get some feedback before I start cutting anything to build his box. The previous owner had some sort of subs installed, and the wiring is all still intact. The line to the battery is there, the ground is there, and the connections and remote line for the amp are all ran and connected to the deck already. I did purchase a wiring kit though in case but it doesn't look like I will need any of it except for the speaker wire to wire the subs themselves to the amp.

The 2 sealed boxes that the audio place sold us cut out the holes too big, and we won't be able to return them for a while (time and distance from us). So I purchased an 8x4 MDF sheet and the screws, glue etc.. to put one together myself. He would prefer a single box to 2 boxes if that is possible. Details are in the list below for the vehicle and subs etc.

Vehicle : 2001 Dodge Ram 2500

Location in the vehicle: Behind the seats

Space available (Length x Width x Height): 63 1/2" L 8 3/4" W 30" H

Subwoofer make and model: Massive UFO 12" shallow sub

Subwoofer Size: 12

Number of Subwoofers: 2

Type of Port (Kerfed, Slot, Aero, etc.): (unsure)

What type of music do you like?: He listens to pretty much everything but probably heavier on rap

Is your goal SPL or Everyday Music?: Everyday

Tuning Freq (Hz): Unsure

Volume : Unsure

Questions:

Recommended air volume is 1 Cubic Ft per sealed box per 12" sub. The only other recommendation I can find on the spec sheets for the sub is a dual ported box which is 3.11 cubic feet. But the dimensions of that box will not fit his space due to the limited depth of 8.75".

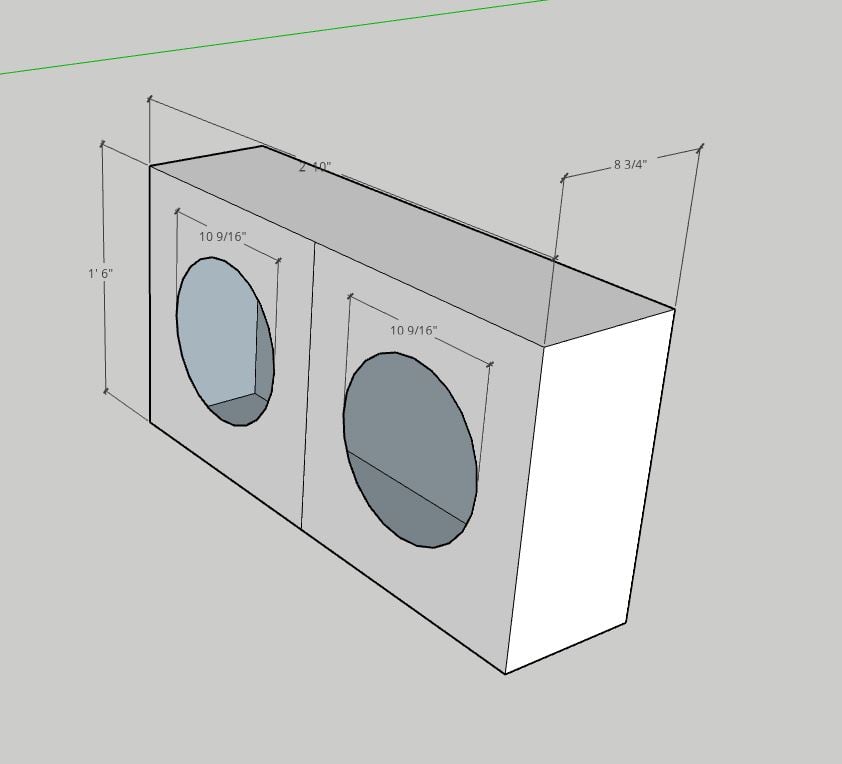

I have come up with a simple rectangle design for the box as follows:

34" long

18" tall

8.75" wide

with the .08 displacement of each sub that would give me roughly 3.13 cubic feet of air space, which is pretty close to the ported recommendations but there is no port on this. Would I add a port or would I need to adjust the dimensions of the box to reduce the air space? Should I add braces inside the box (which would further reduce the cubic space); if so would the dimensions need to be adjusted further?

Would it be better to seal in each sub on the box (ie adding a wall for each sub or a wall between them)?

Please let me know if I am missing anything or if there are any questions. Any help is greatly appreciated!

The 2 sealed boxes that the audio place sold us cut out the holes too big, and we won't be able to return them for a while (time and distance from us). So I purchased an 8x4 MDF sheet and the screws, glue etc.. to put one together myself. He would prefer a single box to 2 boxes if that is possible. Details are in the list below for the vehicle and subs etc.

Vehicle : 2001 Dodge Ram 2500

Location in the vehicle: Behind the seats

Space available (Length x Width x Height): 63 1/2" L 8 3/4" W 30" H

Subwoofer make and model: Massive UFO 12" shallow sub

Subwoofer Size: 12

Number of Subwoofers: 2

Type of Port (Kerfed, Slot, Aero, etc.): (unsure)

What type of music do you like?: He listens to pretty much everything but probably heavier on rap

Is your goal SPL or Everyday Music?: Everyday

Tuning Freq (Hz): Unsure

Volume : Unsure

Questions:

Recommended air volume is 1 Cubic Ft per sealed box per 12" sub. The only other recommendation I can find on the spec sheets for the sub is a dual ported box which is 3.11 cubic feet. But the dimensions of that box will not fit his space due to the limited depth of 8.75".

I have come up with a simple rectangle design for the box as follows:

34" long

18" tall

8.75" wide

with the .08 displacement of each sub that would give me roughly 3.13 cubic feet of air space, which is pretty close to the ported recommendations but there is no port on this. Would I add a port or would I need to adjust the dimensions of the box to reduce the air space? Should I add braces inside the box (which would further reduce the cubic space); if so would the dimensions need to be adjusted further?

Would it be better to seal in each sub on the box (ie adding a wall for each sub or a wall between them)?

Please let me know if I am missing anything or if there are any questions. Any help is greatly appreciated!

Last edited: